Combiner is a device that provides very high coupling efficiency over a wide wavelength range from multiple sources into one output fiber. It is a critical component for pumping high power fiber lasers and amplifiers and for combining laser outputs incoherently. All-fiber combiners are necessary to build monolithic, alignment free and robust fiber laser systems. There are mainly two types of combiners; the first one is pump combiner and the second one is fiber laser (signal) combiner. Pump combiner is generally fabricated with MM single-clad fibers, while laser combiner is fabricated with SM fibers. The principle of pump combiner is delivering the pump light from the fiber coupled laser diodes through the fiber Bragg grating or double-clad active fiber with low loss.

Fig.1: Illustration of pump combiner and laser (signal) combiner

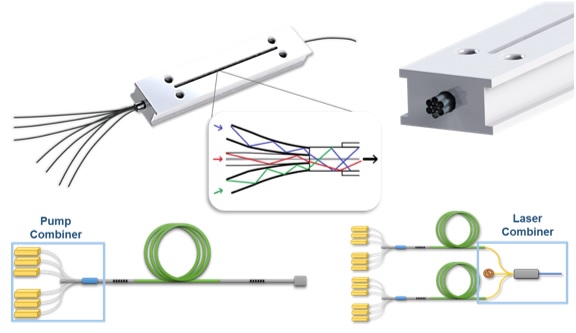

On the other hand, the principle of laser combiner is combining high power lasers without compromising the quality of light. The fabrication of combiner includes seven approaches to integrate double-clad fiber which are side coupling, distributed side coupling, side coupling with bridging fiber, tapered fiber bundle, fiber bundle integrated bridging fiber, side coupled signal fiber and side coupled signal fiber with capillary tube collapsing.

Fig.2: Combiner fabrication approaches; a) side coupling, b) side coupling with bridge fiber, c) fusion of MM fibers to signal fiber, d) fusion capillary tube to signal fiber, e)distributed side coupling, f) tapered fiber bundle and g) tapered fiber bundle with bridge fiber

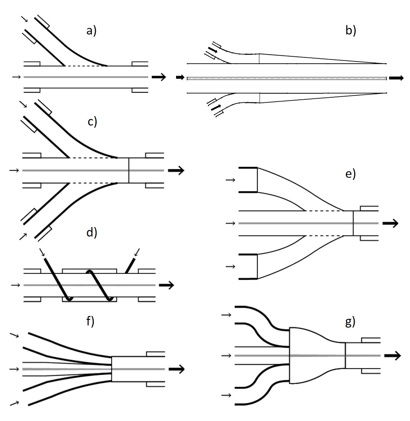

We fabricated 7×1 pump combiners using end-pumping approach as high power fiber laser components. In order to fabricate a pump combiner successfully, the diameter of tapered bundle, the length of taper region, and the capillary type were well designed and calculated. We calculated the desired diameter of the fiber bundle with SolidWorks. The length of the tapered region is calculated by Zemax ray tracing software (Figure 3a). According to these results, Prof. Mehmet Bayındır Group fabricated the capillary tube with low refractive index fluorine doping (Figure 3b).

kW-Class Pump Combiner for High Power Fiber Lasers

Fig.3: a) Solidworks and Zemax design of typical (7×1) combiner, b) Fabricated fluorine doped capillary tube

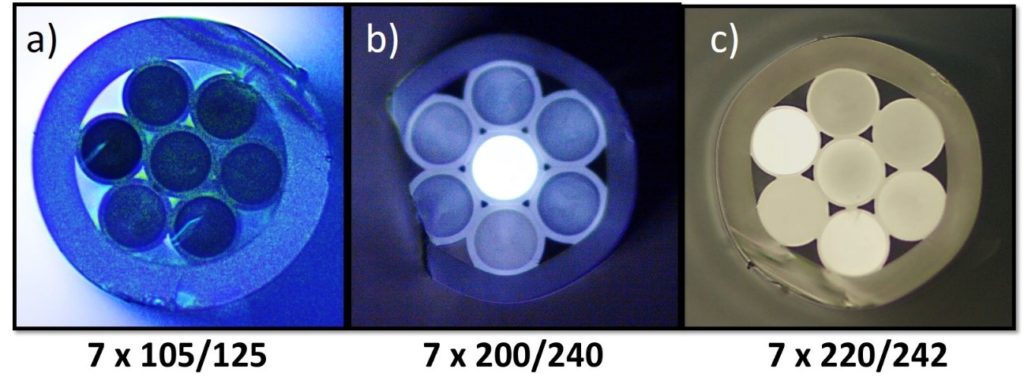

Fabrication of a 7×1 pump combiner was performed in several steps including tedious optimization of tapering, cleaving and splicing processes. Three types of pump combiners which have 105/125 µm, 200/240 µm and 220/242 µm core/cladding diameter input fibers, 400 µm output fiber were fabricated (Figure 4).

Fig.4: Cross-section of combiners that have a) 105/125 µm, b) 200/240 µm and c) 220/242 µm input fibers.

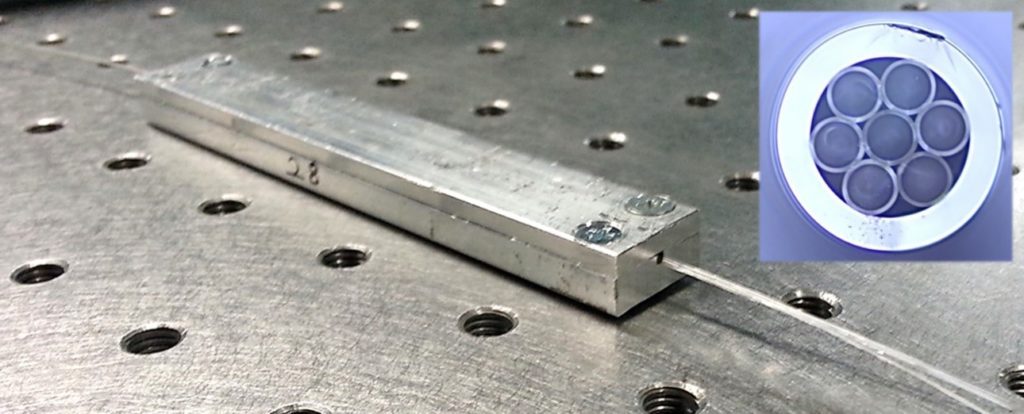

We have fabricated and packaged 7×1 kW class pump combiner which have 105/125 µm input fiber and 20/400 output fiber and it is shown in Figure 5. In order to manage thermal loading on combiner, we have designed and fabricated metal housing for all types of combiners.

Fig.5: Packaged 7×1 pump combiner having 105/125 µm input and 20/400 output fiber.

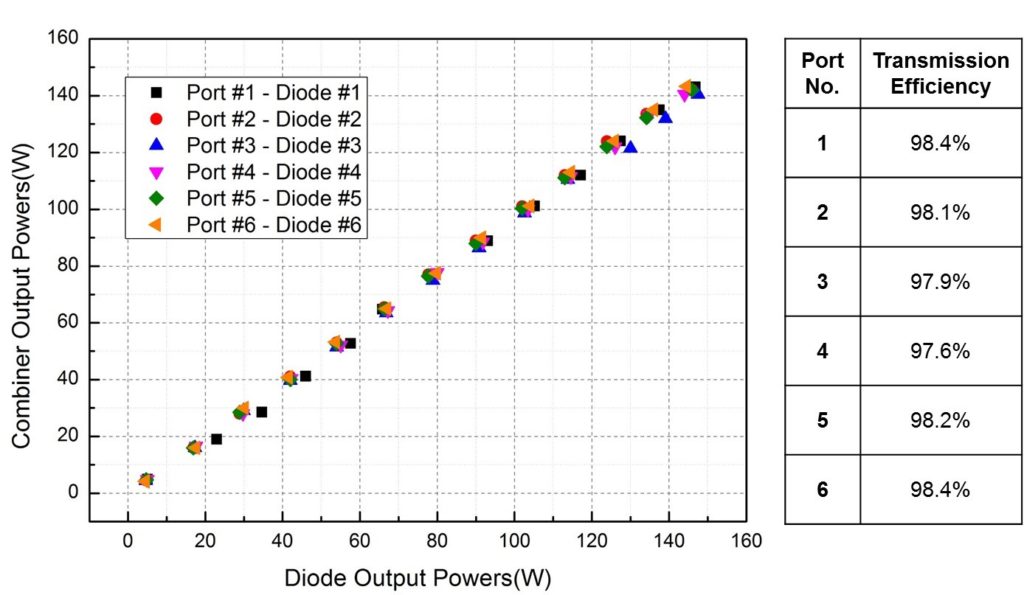

This pump combiner was first tested with six laser diodes which have output 105/125 µm fibers and around 140 W maximum power. The 7×1 pump combiner was integrated to the high power fiber laser system developed in our laboratory. Pump source limited power handling capacity of this pump combiner was measured as 850 W with an overall efficiency of 98 % and characterization values of each port are shown in Figure 6. In addition, the same pump combiner was adapted to a high power fiber laser system which was built by using an in-house fabricated active fiber.

Fig.6: Combiner output powers vs. laser diode output powers graph for each input port and laser diode. Calculated transmission efficiency of each input port of combiner.

We have also constructed a high power fiber laser which was operated at 1080 nm wavelength and 600 W output power by using this combiner. Furthermore, the same pump combiner was adapted to a laser system which was built by using an in-house fabricated active fiber. This fiber laser was operated at 1064 nm and its FBG-limited maximum output power was 420 W. Thermal load on combiner when it was operated under maximum power of all laser diodes was only 80C.

kW-Class Fiber Laser (Signal) Combiner

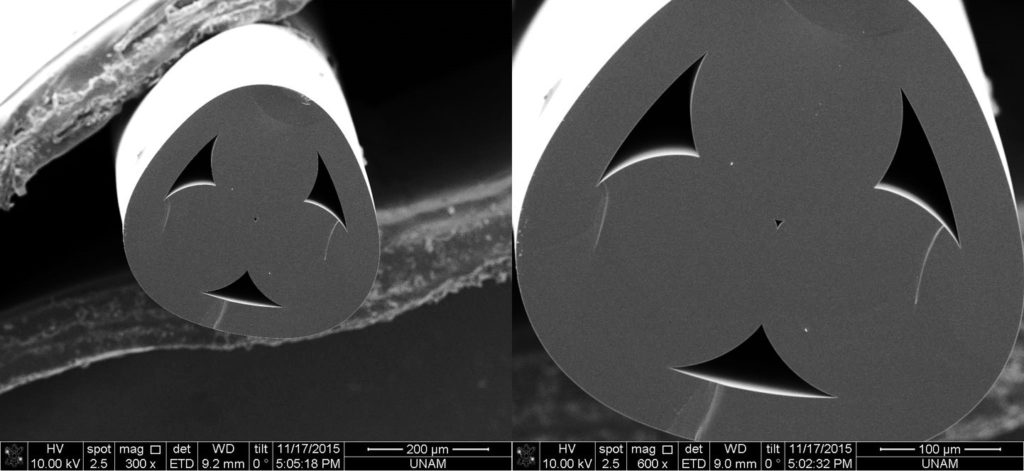

We fabricated kW class 3×1 fiber laser combiner which have 240 µm input and 400 µm output fiber. In order to fabricate a signal combiner successfully, the diameter of tapered bundle, the length of taper region, and the capillary type were again designed and calculated. Also, low refractive index fluorine doped capillary tube was also used. The scanning electron microscope images of 3×1 laser combiner are shown in Figure 7.

Fig.7: Scanning electron microscope images of 3×1 laser combiner cross-section.

In order to combine two in-house built high power fiber lasers, the 3×1 laser combiner was fabricated and it was characterized in terms of geometrical structure, power handling capacity, thermal load at splice point and its input port efficiency. We have used two ports of this combiner with a launched power of approximately 500 W from each of them.